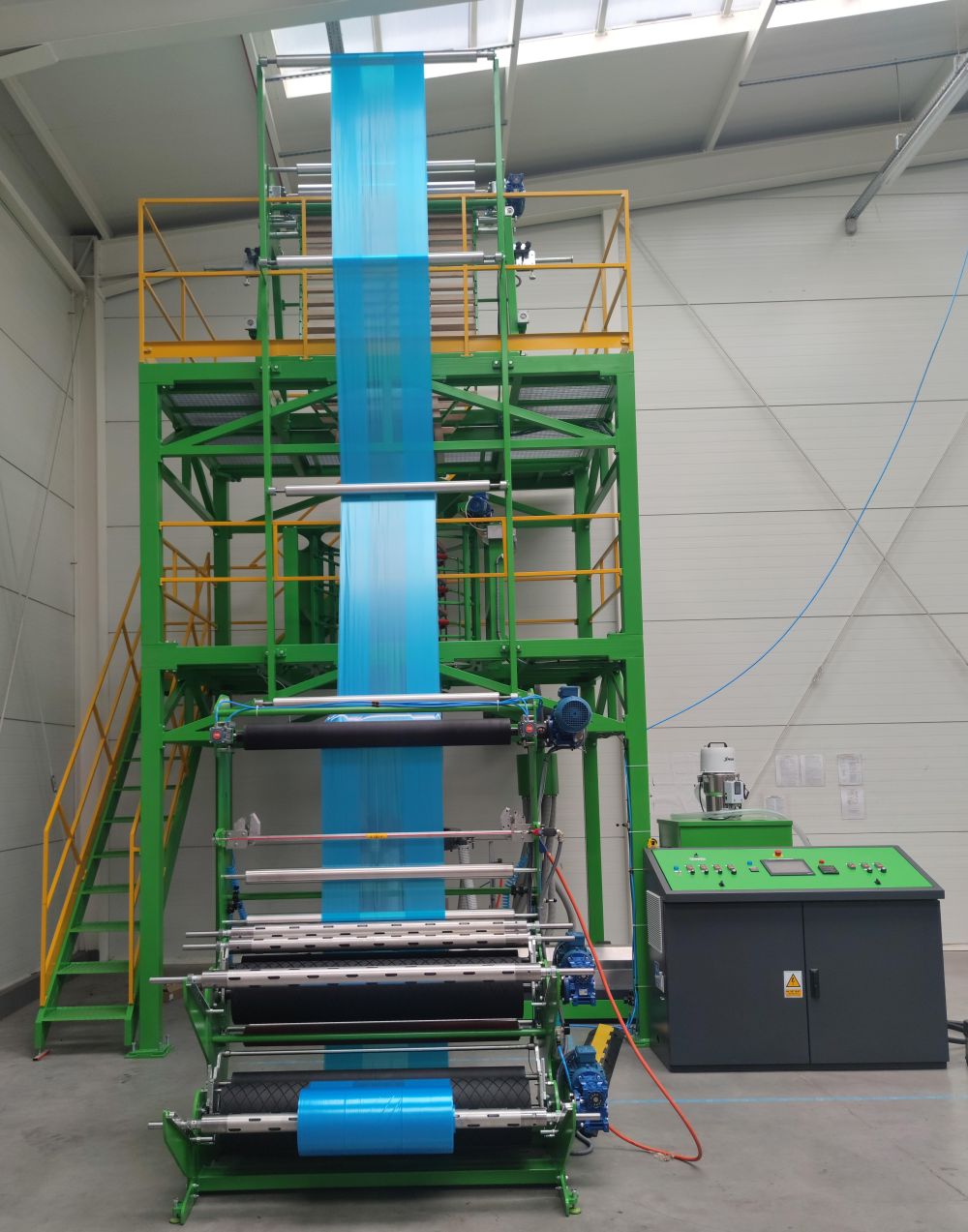

Extruders for the production of LDPE and HDPE films

purpose:

production of film in the form of a sleeve, half sleeve, tape

unique system of pumping air into the bubble while the head is rotating

- Aptruder 56-1000-2 series

- compact extruders on a common frame

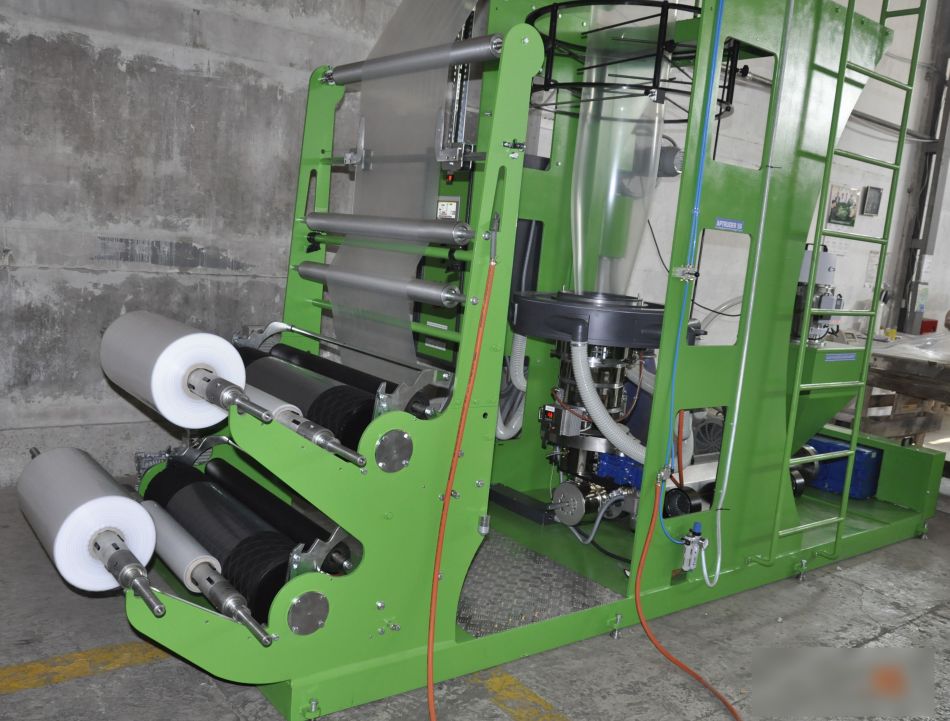

- rotary or stationary heads

- die sizes: LDPE 120-180 HDPE 80-150

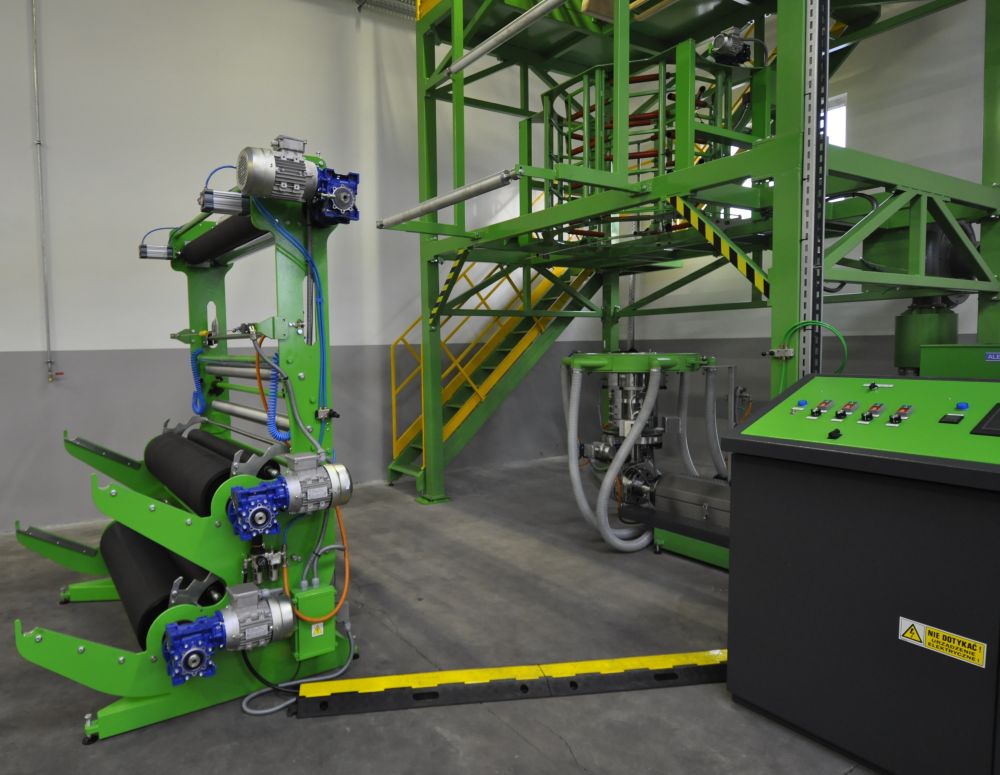

- two-arm winder

- side cutting knifes

- bimetallic screws and barrels

- large surface candle filter

- Siemens or ABB or WEG motors AC

- Omron drives

- energy efficient stainless steel heaters

- 7″ or 10 ” touch panel

- embossing unit for HDPE

- pneumatic shafts pcs. 4

- banana rollers pcs. 2

- 2.1 kVA corona treatment two-sided

- classic free-standing extruders with 56 mm, 70 mm, 80 mm, 90 mm screws

- automatic and manual free-standing winders

- two arm winders of the “back to back” or one-side type

- electronic tension adjustment

- 1-3 layers A , AB , ABC , ABA

- roll width 1150 mm , 1300 mm , 1600 mm , 1800 mm

the final specification is always determined individually.